In order to produce mechanical power, an internal combustion engine (ICE) needs fuel and air (oxygen). The amount of fuel injected into the engine depends on the amount of air drawn into the cylinders. There is no point injecting too much fuel, if there is not enough air, since it will not burn (because it will lack oxygen).

Depending on the method of getting air into the cylinders, there are two main types of internal combustion engines:

- naturally aspirated (also called atmospheric engines): in which the air is drawn (sucked) into the cylinders due to the piston movement, which creates volume while moving towards the bottom dead center (BDC)

- forced induction (also called supercharged): in which the air is forced (pushed) into the cylinders by a compressor

For naturally aspirated engines, the intake air pressure (absolute) is always less than the atmospheric pressure (1.0 bar). At idle speed, the intake air pressure is around 0.5 bar and gets close to 1.0 bar during full load (Wide Open Throttle – WOT).

For supercharged engines, the intake air pressure (absolute) range depends on the type of engine. For example:

- gasoline (SI – spark ignition) engine: 0.5 bar at idle speed and 1.5 – 2.5 bar at full load

- diesel (CI – compression ignition) engine: 1.0 bar at idle speed and 2.5 bar at full load

The boost air pressure provided by the turbocharger can be relative to the atmospheric pressure or absolute. A boost pressure of 1.5 bar (relative) means 2.5 bar (absolute value) since:

\[2.5 \text{ bar (absolute intake pressure)} = 1.5 \text{ bar (boost)} + 1.0 \text{ bar (atmo)}\]The maximum boost pressure (relative) is around 1.5 bar for passenger vehicles, going up to 2.5 – 3.0 bar for high performance engines.

Intake air supercharging can be obtained with:

- mechanically driven superchargers: the supercharger (compressor) is driven by the crankshaft; the supercharger and the engine have a direct (mechanical) link

- turbochargers: the compressor is mechanically linked to a turbine, which is set in motion by the exhaust gas flow; there in no direct link between the compressor and the crankshaft, the turbocharger and the engine (crankshaft) are linked thermodynamically

- pressure-wave supercharger: the compressor is driven by the exhaust gasses but there is also a need for a mechanical link between the engine and compressor in order to synchronize the supercharger; the engine and supercharger are linked thermodynamically and mechanically

The main advantage of supercharging is that more air can be introduced into the engine, which allows more fuel to be burned thus increasing the specific power of the internal combustion engine.

In this article we are going to focus on the turbocharging technology since more than 99 % of the supercharged vehicles sold today are equipped with turbochargers.

History of turbocharging

The idea of turbocharging is not new, intake air forced induction came into horizon together with the internal combustion engine. In 1896 Goettlieb Daimler and Rudolph Diesel started the research activities on how to increase the engine power and reduce fuel consumption by supercharging the intake air.

The first successful automotive implementation of supercharging came into 1925 when the Swiss engineer Alfred Bachi integrates a turbocharger on an internal combustion engine and increases its output power with 40 % (compared with the naturally aspirated version). This event gave the start for most of the automotive manufacturers to consider turbocharging technology for their internal combustion engines.

In USA market, in 1962, Chevrolet Corvair Monza and Oldsmobile Jetfire mark the debut of turbocharged vehicles. Chevrolet Corvair Monza was powered by a 2.3 liters, straight 6 cylinders supercharged gasoline engine. The maximum power output was 150 HP at 4400 rpm and the maximum torque output was 285 Nm between 3200 and 3400 rpm. Oldsmobil Jetfire was powered by a 3.5 liters, V 8 cylinders supercharged gasoline F-85 engine. The maximum power output was 215 HP at 4600 rpm and the maximum torque output was 285 Nm at 3200 rpm.

Despite having a remarkable power output, due to low reliability, the supercharged engines were not able to penetrate the automotive industry market and were replaced by naturally aspirated engines.

A new wave of supercharged engines started in 1973 as a reaction to the oil crisis. Commercial diesel engines started to be equipped with turbochargers because they had significant lower fuel consumption compare to the naturally aspirated versions.

Starting with 1970 turbocharged engines are being used also in motorsport, especially in F1 races. This event helps pushing the usage of the turbocharger in the automotive industry which eventually becomes a standard for high performance engines. Even if turbocharging was adding significant boost to the output power, the high fuel consumption of the (gasoline) engines and the turbo-lag behavior (delay in engine acceleration) were seen as a drawbacks (compared to naturally aspirated engines) and stopped vehicles manufacturers to use turbochargers on a wider scale.

The real debut of the passenger vehicles with turbocharged engines came in 1978 with the release of MercedeBenz 300 SD. This was the first passenger vehicle equipped with a turbocharged diesel engine produced in large numbers. Three years later, VW Golf Turbodiesel is released to the market. Adding turbocharging to diesel engines increased the overall efficiency of the engine, helped reduce pollutant emissions and improved driving experience.

How engine power can be increased

Engine power output relates to a number of mechanical factors, fuel properties and intake air density. For four-stroke cycle engines, the engine power Pe [W] is:

\[P_e = \frac{n_f \cdot n_v \cdot N_e \cdot V_d \cdot Q_{HV} \cdot \rho_{a,i} \cdot (F/A)}{2} \tag{1}\]where:

ηf [-] – fuel conversion efficiency

ηv [-] – volumetric efficiency

Ne [rot/s] – engine speed

Vd [m3] – engine volumetric capacity (swept volume)

QHV [J/kg] – fuel heating value

ρa,i [kg/m3] – intake air density

F/A [-] – fuel air ratio

From the mathematical formula (1), we can see that the engine power can be increased in several ways:

- by decreasing engine losses (higher fuel conversion efficiency)

- by improving air intake capacity of the engine (higher volumetric efficiency)

- by increasing the engine speed (lower friction losses and components inertia)

- by increasing the engine capacity

- by increasing the energy content of the fuel (higher heating value)

- by increasing the intake air density

- by increasing the fuel-air ratio

For a given engine, turbocharging can improve the engine power output by increasing the intake air density and improving the engine’s efficiency by lowering pumping losses.

How turbocharging works

Turbocharged engines rely on a turbocharger to compress intake air. The simplest arrangement is using a single stage, fixed geometry, turbocharger with boost pressure limitation.

There are different types of turbocharging systems, classified after:

- number of pressure increase stages:

- single stage turbocharging

- dual-stage stage turbocharging

- intake air pressure limitation/control

- with pressure limitation

- with pressure control

- compressed air cooling

- without intercooler

- with intercooler

- number of turbine scrolls

- single scroll (flow) turbine

- twin-scroll (flow) turbine

- geometry of the turbine housing

- fixed geometry turbine

- variable geometry housing

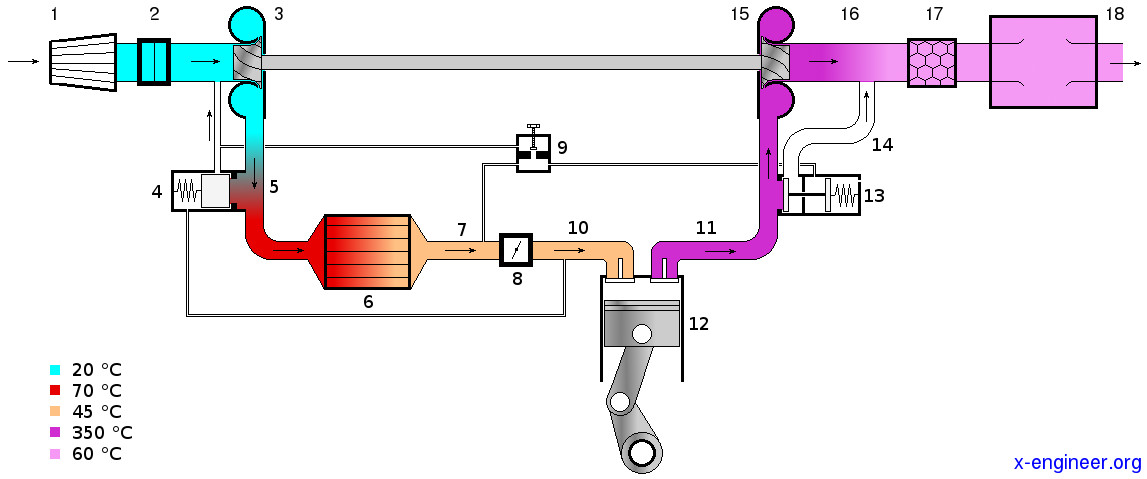

In the example below we are going to describe how a single stage, fixed geometry, wastegate controlled pressure (limited), single scroll turbine, intercooled turbocharged gasoline engine works.

where:

- air filter

- mass airflow sensor

- compressor

- blow-off valve (pop-off valve)

- boost pipe

- intercooler

- charge pipe

- throttle

- boost pressure limit controller

- intake manifold

- exhaust manifold

- cylinder

- wastegate

- bypass duct

- turbine

- dump pipe

- catalytic converter

- muffler

The compressor (3) and the turbine (15) are mechanically connected through a rigid shaft. At the end of the exhaust cycle, the exhaust gases are pushed out from the cylinder (12) through the exhaust manifold (11) and through the turbine (15). The exhaust gas flow (kinetic energy) will hit the blades of the turbine, forcing it to spin. In the same time, having a fixed connection, the compressor (3) will spin, compressing the intake air in to the intake boost pipe (5).

Compressing the air will increase its temperature. This phenomena is not desired because the higher the temperature of the air, the lower the its density, which means fewer air molecules are available for combustion. In order to increase the density of the intake air, an intercooler (6) is placed before the throttle (8). The intercooler is a air-to-air heat exchanger which cools down the compressed intake air before going into the engine.

The boost pressure (air intake) is controlled (limited) in two situation by different components:

- when the driver lifts off the accelerator pedal (after a vehicle acceleration event), the throttle closes suddenly and the intake pressure builds up quickly, since the compressor is still spinning; this can cause air flow reversal in the compressor (surge) which can damage it; to avoid the situation, if the boost pressure builds up to a maximum limit in the boost pipe and there is intake manifold vacuum (throttle closed), the blow-off valve (4) opens, recirculating the compressed air in the compressor

- when the engine is operating at high speed and load, the compressed intake air in the charge pipe (7) is limited to a maximum amount through the wastegate (13); at high speed and load, the pressure and flow of the exhaust gases are high, which causes the turbine to spin very fast; the compressor will also have a high speed, which turns into high pressure of the intake air; to limit the speed of the turbine thus boost pressure, the wastegate is opened, which redirects part of the exhaust gases around the turbine, through the bypass duct (14)

The animation below shows the flow of the intake air and exhaust gases. In this animation there is no intercooler present.

where:

- exhaust manifold

- turbine housing

- turbine

- shaft

- compressor housing

- compressor

- intake manifold

- intake pipe

- air filter

- turbocharger

The operating principle of the turbocharger is based on the principle of momentum conservation. Part of the enthalpy (energy) of the exhaust gases is converted by the turbine into mechanical energy used to drive the compressor. The rotation of the compressor will draw air from the atmosphere and compress it before going into the engine.

The intercooler is usually mounted in front of the vehicle under the engine cooling radiator. (see picture below).

where:

- turbocharger

- boost pipe

- intercooler

- charge pipe

- exhaust catalyst

Depending on the type of the engine, cylinder displacement and vehicle architecture, the intercooler can be split into two components.

In terms of engine torque response, the intercooling system brings a disadvantage compared to naturally aspirated engines. The extra volume of air of the air cooling system increases the total inertia of the intake air, so it takes some extra time for the air flow to gain speed when engine acceleration is required.

Turbo lag is the delay in engine acceleration after the driver presses the accelerator pedal. This delay is caused by the inertia of the air and by the time taken by the compressor to accelerate (mechanical inertia) and boost the intake air pressure.

The exhaust-gas turbocharger has four main parts (components):

- housing

- turbine

- compressor

- boost pressure control (limit) device

The turbocharger housing is made up from three section:

- compressor housing

- bearing (central) housing

- turbine housing

The (central) bearing housing contains the bearings and the sealing elements of the shaft. The bearings are plain and can be axial (in the center of the shaft) or radial (in the end of the shaft). The bearings are floating-type, which means that they float on a layer of engine oil. Additional to the lubrication function, the oil is also cooling the turbocharger by being connected to the oil circuit of the engine.

where:

- compressor

- compressor housing

- bearing (central) housing

- turbine housing

- turbine

- wastegate

In the example above, the central housing contains axial and radial bearings (golden color) and also galleries for water cooling. High performance turbochargers need water cooling to keep the temperature within safe limits. Up to 820 °C the bearings can operate normally, only relying on the oil cooling. Water-cooled turbochargers are used for engine applications where the exhaust-gas temperature can reach 1050 °C.

The compressor housing can be made from aluminium since has to withstand lower temperature, while the bearing and turbine housing have to be made from cast iron.

The impeller of the compressor is produced through casting, from an aluminium alloy. For high temperature applications the impeller can be milled from a titanium alloy. The turbine wheel is made from steel with high concentrations of nickel (in order to withstand high operating temperatures).

Since the speed of the compressor-shaft-turbine assembly can be between 10000 rpm (at idle speed) and 300000 rpm (maximum engine speed) it is critical to have a low mass (inertia). The low inertia is also beneficial in during the transient phases of the engine operation, when the compressor needs to be accelerated as fast as possible to provide the required boost pressure.

where:

- turbine outlet

- wastegate control rod

- pneumatic unit

- compressor inlet

- compressor outlet

- turbine inlet

The opening and closing of the wastegate is usually performed with a pneumatic unit (cylinder), through a control rod. If the boost pressure is only limited to a maximum value (e.g. 2.5 bar absolute pressure), the pneumatic cylinder is connected directly to the intake manifold, and the wastegate actuation is performed function of the intake air maximum pressure.

Modern engines have electronic control of the boost pressure. An additional electro-pneumatic valve is used (controlled by the engine control module) to regulate the pressure within the pneumatic unit. Thus, the boost pressure can be controlled more precise, between a minimum (e.g. 1.1 bar) and a maximum (e.g. 2.5 bar), relatively independent of the engine operating point.

There are also turbochagers which feature electronic control of the wastegate by using electric motors. The electronic control of the wastegate has the advantage of very good precision and very good response time (compare to pneumatic control).

Turbocharging effects on engines

Increasing the air intake pressure on a gasoline engine has the effect of increasing the overall compression ratio of the engine. Having a very high compression ratio can cause detonation. To avoid this phenomena, turbocharged gasoline engines have lower compression ratio, compared with their naturally aspirated versions.

Turbocharging also leads to an increased air intake temperature. The combination of high air intake temperature and pressure leads to an increase of the combustion pressure and temperature. For this reason, turbocharged engines have higher demands with regards to engine cooling. The cooling system of a turbocharged engine must be able to dissipate more heat compared with a similar naturally aspirated engine (same capacity).

In terms of pollutant emissions, turbocharging tends to increase the amount of nitrogen oxides (NOx) in a gasoline engine and decreases the carbon monoxide (CO) and hydrocarbons (HC) in a diesel engine.

For high altitude (low atmospheric pressure) regions, turbocharging is beneficial since it compensates for the low density of the air. The benefit of turbocharging is more obvious in mountainous countries where air density is lower hence engine power is significantly affected.

In a compression ignition (diesel) engine, since only air is compressed, the detonation doesn’t occur at all. On the contrary, the higher the density of the compressed air inside the cylinder, the better the combustion process. Also, since diesel engines do not have a throttle valve to regulate the amount of air, the turbine spins faster at medium engine load allowing faster pressure buildup in case of accelerations.

Advantages of turbocharging

Turbocharging is one of the main technologies for “downsizing”. Engine “downsizing” means that the capacity of the engine is lowered but the power output remains the same (or increases) and the fuel consumption decreases.

Let’s take as example two gasoline engines and explain the advantages of the turbocharged engine.

| Manufacturer / Model year | Renault / 2009 | |

| Model | Clio | |

| Engine type | 1.6 16V MPI | 1.2 16V TCe |

| Engine capacity [cm3] | 1598 | 1149 |

| Fuel type | gasoline | |

| Air intake | naturally aspirated | turbocharged |

| Maximum power [HP] | 110 | 100 |

| Engine speed for maximum power [rpm] | 6000 | 5500 |

| Maximum torque [Nm] | 151 | 145 |

| Engine speed for maximum torque [rpm] | 4250 | 3000 |

| Specific power [HP/liter] | 68.84 | 87.03 |

| Specific torque [Nm/liter] | 94.49 | 126.2 |

| Vehicle mass [kg] | 1150 | 1090 |

| Combined fuel consumption [L / 100 km] | 6.7 | 5.8 |

| CO2 emissions [g/km] | 160 | 137 |

| Maximum vehicle speed [kph] | 190 | 184 |

| Acceleration time 0-100 kph [s] | 10.2 | 11 |

From the table above we can see that the specific power and torque are higher for the turbocharged engine. This means that, for the same volumetric capacity of the engine, the turbocharged version outputs more power and torque. Also, the maximum power and torque, for the turbocharged engine, are obtained at lower engine speed. This brings the advantage of better vehicle acceleration from low engine speeds.

Being able to control the intake air pressure, allows to obtain a maximum torque zone, starting from low engine speeds up to medium speed. Usually, turbocharged engines have the maximum engine torque within a speed range (e.g. 1800 – 3500 rpm) rather than a single point, as for naturally aspirated engines (e.g. 4500 rpm).

The turbocharged engine has lower fuel consumption for similar output torque and power, due to better efficiency. The lower capacity of the turbocharged engine means smaller components, which means lower engine friction. Also, the pumping losses of the turbocharged engine are lower at medium loads (where absolute intake air pressure is above 1.0 bar), which improves the overall efficiency.

Turbocharging has proven to be a very efficient technology for engine power increase and reduced fuel consumption. In the near future all of the internal combustion engines will have one form or another of turbocharging.

Don’t forget to Like, Share and Subscribe!

Jason

The corvair never used a straight 6 engine…. they used a 6 cylinder air cooled boxer engine.

Amir Barakati

Thanks a lot for this valuable technical text. I studied whole the text deeply. I think there is a one unclear matter in this part:

“when the engine is operating at high speed and load, the compressed intake air in the charge pipe (7) is limited to a maximum amount through the wastegate (13)”

I think there is not any direct connection between components 7 & 13. here components No. 9 is main part to control (limit) the boost pressure amount in part (7).

with considerations this note which Part 9 is controller of both boost intake air and exhausted one, I think this sentence need to be corrected.

please inform me the result.

Finally, let I appreciated your attempts in sharing information.

Regards

Amir

Marcello Leone

This is probably an old comment and you may know the answer now but a wastegate controls the the boost pressure of the intake using springs and intake manifold pressure to vary the speed of the turbo by diverting the exhaust gases before they reach the turbo

“when the engine is operating at high speed and load, the compressed intake air in the charge pipe (7) is limited to a maximum amount through the wastegate (13)”