In this article we are going to explore why a battery electric vehicle (BEV) is the future solution for mobility. It is not mandatory, but a good understanding of how the battery electric vehicles work, will be beneficial before going through this article. Therefore, try to read the article Anatomy of a battery electric vehicle (BEV) in order to get the basic principles of battery electric vehicles.

Battery electric vehicles (BEVs), also known are pure electric vehicles, are the long term solution for mobility. Compared with a vehicles with internal combustion engine (ICE), a BEV has several advantages but also some disadvantages.

Advantages of a BEV compared with an ICE powered vehicle

Motor Efficiency

Alternative current (AC) electric motors, with permanent magnet or induction rotors, have a very high overall efficiency. A typical permanent magnet electric motor, used for traction, has a minimum efficiency of around 70-75% and a maximum of 95-97%.

By contrast, the efficiency of an internal combustion engine is much lower. Depending on the type of the engine (compression or spark ignition), fuel injection system (direct or indirect), air intake type (atmospheric or boosted) and the operating point (speed and torque), the efficiency of an internal combustion engine can be anywhere between 10% and 45%.

An electric motor can be easily be operated at an average efficiency of 85-90% (on a driving cycle). In the same time, the average efficiency of the engine will be probably between 25-30%. The conclusion is that the efficiency of an electric motor, for automotive applications, is on average three times higher, compared with an internal combustion engine.

Dynamic performance (vehicle acceleration)

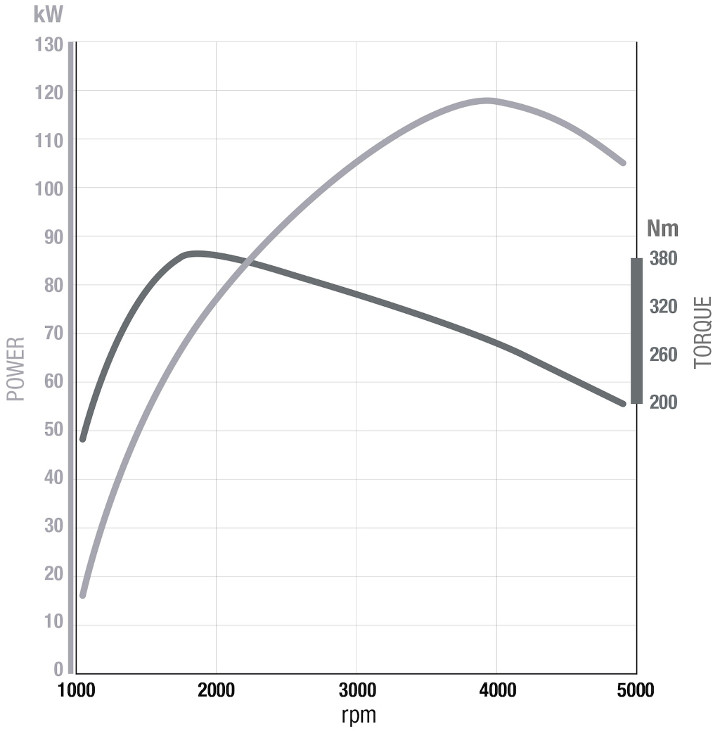

A permanent magnet electric motor has an ideal traction characteristic. Also, at zero speed, the electric motor can deliver the maximum available torque, which translates in very good launch performance of the vehicle.

An electric motor is capable of providing a peak torque for a limited amount of time (a couple of seconds) and a continuous torque (as long as there is supply energy). The peak torque requires very high amount of current to be draw from the battery, which produces high temperatures in the power electronics and motor. To protect the components, the peak torque is limited in time, but it’s available enough to boost the acceleration performance of the vehicle.

On the other hand, an internal combustion engine can not deliver maximum torque from minimum speed (idle). They also need more time to reach maximum torque because of mechanical components and intake air dynamics (inertia, turbo-lag, etc.).

Even the best, state of the art, internal combustion engine, can not outperform an electric motor in terms of traction characteristics (torque and power). From this point of view, the electric motor is clearly a better solution for automotive applications.

Another important factor is the torque / power density. Compared to an internal combustion engine, an electric motor has at least twice the gravimetric [Nm/kg, kW/kg] or volumetric [Nm/l, kW/l] torque / power density. For the same output torque / power, the electric motor is much more lighter and smaller.

Reliability

Legend:

- power electronic controller

- stator

- rotor

- single speed gearbox and differential

Having less moving parts, compared with an internal combustion engine, an electric motor has fewer sources of possible failures. Also, due to the high torque and high speed characteristic of the electric motor, there is no need for a multi stage gearbox, a single step mechanical gearbox could be enough for traction requirements.

The internal combustion engine has many moving parts and also additional systems (fuel system, exhaust gas after-treatment system, etc.) which can lead to possible failures. Also, due to its torque characteristic, an engine powered vehicle requires a multi step gearbox, which is an additional source of possible failures.

Torque vectoring

For an all wheel drive (AWD) battery electric vehicle, stability during cornering can be improved by controlling the torque at the wheels. Also, compared to an internal combustion engine, an electric motor has faster torque response and can provide negative torque.

The internal combustion engine has limited contribution to the vehicle stability, most of the times it’s only reducing the amount of torque delivered.

Energy recuperation & brake regeneration

Another significant advantage of an electric machine is that it can be reversible. This means that can produce torque if it’s supplied with electrical energy or it can produce electrical energy when it has an input torque (due to vehicle inertia). When the electric machine is producing torque it’s in motor mode, when it’s producing electrical energy it’s in generator mode.

As you can see in the image above, the negative torque can be as high as the positive torque. This means that the electric machine can produce a significant amount of braking torque. Being able to control the braking torque to any level on the map, an battery electric vehicle can have the following functions when driver lifts off the accelerator pedal:

| Mode | Activation conditions | Description |

| Coasting |

|

|

| Overrun |

|

|

| Regen braking |

|

|

All these modes can be achieved with an electric machine quite easily, only through torque control. The activation modes depend on the manufacturer but the behavior is common to all.

Service maintenance

Having less moving parts and components, a battery electric vehicle is easier and cheaper to maintain. On the other hand, in order to be preserved in a good operating condition, the internal combustion engine needs regular service / maintenance intervals (air and fuel filters change, oil change, etc.).

Pollutant emissions

Since it’s only using electrical energy for propulsion, there are no emission regulations which apply to a battery electric vehicle.

Autonomous vehicles

Since the automotive industry is going clearly towards autonomous vehicles, using a battery electric vehicle has some clear advantages. The main advantage is that a BEV can be charged wireless, which removes a lot of the possible hazards brought by electric contacts. Moreover, taking out the liquid fuel from the equation, improves significantly the safety of a vehicle’s energy refill operation.

Disadvantages of a BEV compared with an ICE powered vehicle

It is obvious that using electric machines instead ICEs give vehicles tremendous advantages in terms of efficiency, dynamic performance (torque and power) and reliability.

Energy source

The main drawback of a battery electric vehicle is the energy storage system, the high voltage battery.

Compared to gasoline and diesel fuels, for the same volume, the energy stored in a battery is around 10 times less. In the figure below we can see that batteries have bigger volume, mass and store less energy compared with gasoline and diesel fuel.

The poor energy density of the battery has a direct impact on the vehicle range. For a BEV, with the current performance of the battery cells, in order to have a decent range (200 – 300 km), the battery pack will turn out to be quite heavy and bulky.

Further, in cold environments, the range of the BEV is decreased further due to the degradation of battery performance (at low temperatures) and usage of electrical energy for heating (cabin, battery).

Recharge time

The recharge time of the high voltage battery is another major drawback of a BEV. For an ICE powered vehicle, the time to fill up the fuel tank takes less than 10 minutes. In the case of a battery powered vehicle, the recharge time can take between 30 minutes (“fast charging”) and about 8 – 10 hours (“normal charging”).

Another concern of the battery powered vehicles is the charge/recharge cycle. If the battery is often charged with a high current (“fast charging” method) the energy storage capacity decreases in time.

Charging infrastructure

Charging infrastructure is currently another issue for battery electric vehicles. There is a clear need for more charging points which should accommodate the increase number of BEVs. Also, the distribution of the charging point must be planned taking into account traffic management data.

For any country, there should be electric vehicle charging points (EVCPs) hubs in and around major cities. The charging hubs should allow a BEV to travel across the country, with the maximum distance between two charging points being around 80 km (below actual range of current BEV on the market).

Moving further

It is clear that a BEV has major obstacles to overcome in terms of energy storage, battery lifetime and charging infrastructure. Nevertheless progress is being done in all areas.

Battery technology is also developing at a sustained pace. The volumetric energy density for Lithium-ion battery cells improved from 190 Wh/l, in 1991, to 580 Wh/l, in 2005. Current production lithium-ion cells have around 676 Wh/l or more.

Currently, marketed BEV have a high purchasing price mainly due to the high voltage battery price. However the price is estimated to decrease year by year and will go below 300 – 200 USD per kWh by 2020. When battery prices will become competitive and the overall price of an electric vehicle will be similar with a ICE powered vehicle, the market will shift towards BEV.

The Electric Vehicles Initiative (EVI) is a multi-government policy forum dedicated to accelerating the introduction and adoption of electric vehicles worldwide.

EVI is one of several initiatives launched in 2010 under the Clean Energy Ministerial, a high-level dialogue among energy ministers from the world’s major economies. EVI currently includes 15 member governments from Africa, Asia, Europe, and North America, as well as participation from the International Energy Agency (IEA).

EVI estimates an exponential growth of battery electric vehicle sales by 2020. From around 1 million BEVs sold in 2015 approx. 6 million battery electric vehicles will be sold in 2020. The biggest market for BEV will be China followed by USA, Japan and European countries. Furthermore China and USA will count in 2020 for half of the total BEV sales (around 3 million vehicles).

Currently, the energy storage system (high voltage battery) is the main reason for which battery electric vehicles are not a better alternative to ICE powered vehicles. As the energy density of the batteries goes up and the price goes down, there will be a tipping point from which ICE powered vehicles are going to become obsolete.

The question is WHEN rather than IF this will happen. That moment will probably come around the year 2025.

For any questions, observations and queries regarding this article, use the comment form below.

Don’t forget to Like, Share and Subscribe!

ABDULLAH JUBAIR

is it possible to have the motor efficiency mapping look up table. it is for academic purposes.

milind pagare

Very nice explanation

Nitin Panchal

Question regarding the Battery life and after the life situation, What can be done in terms of environmentally, Can be more headache than CO2 emission issue.